Henan Zhengyi building materials Machinery Manufacturing Co., Ltd. is a technical entity to develop and produce aerated concrete equipment. It has its own professional research and design team of aerated block equipment, and has technical support and partnership with Northeast Architectural Design Institute. The company can provide customers with high-quality autoclaved aerated block production equipment and technical services. we can formulated advanced technological process of aerated block , and the technical level is in the leading position in China.the company takes science and technology development as the leader,quality as the foundation ,reputation as the guarantee,service as the center ,win the trust of domestic and foreign markets and serve the coustomers

ZY1100 Automatic hydraulic press machine

Product Description

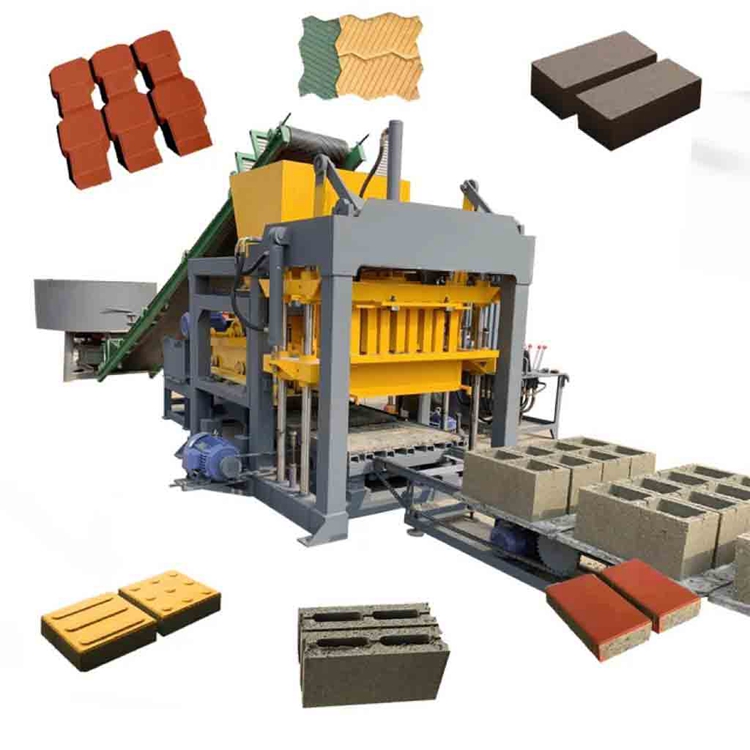

The "Zhengyi" brand Large tonnage hydraulic brick press machine is a four-column press with hydraulic transmission, which is a new model with double-sided pressurization, high energy saving, fast and low price. The machine adopts optimized hydraulic transmission, which has the characteristics of saving power, low noise and low failure rate. Imported PLC automatic control system has high technology content and low labor intensity, thus greatly improving the output and quality of brick making. The brick pressing process of the static brick press has the characteristics of stable force, high pressure and high degree of automation, so it has the characteristics of good product quality, high strength, high yield and standard shape and size.

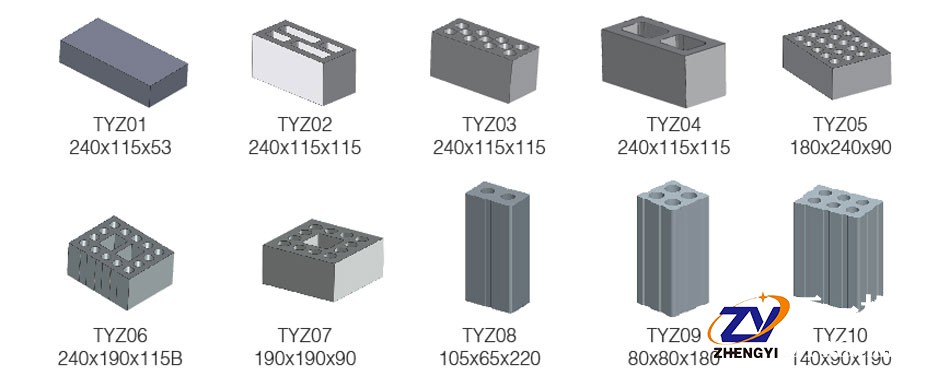

There are many kinds of Large tonnage hydraulic brick press machine, and standard bricks, blind hole bricks and other special-shaped products can be made by changing the mold. Changing different molds can press different briquettes and hollow bricks. This machine does not need a pallet, and bricks can be piled directly, which can save a lot of investment. High strength and good stability. The hydraulic station system adopts a unique cooling system, so that the oil temperature is not easy to rise. The oil circuit is redesigned with a quick system, which makes the operation more worry-free and saves more labor resources.

Main functions and uses main performance

1, automatic demoulding, automatic brick.

2, the speed of demoulding and brick discharging is improved.

3, set machine, electricity, liquid in one, start-up automatic cycle operation.

4. It has the advantages of convenient operation and maintenance, reasonable structure and beautiful appearance.

5. Advanced electro-hydraulic control and accurate hydraulic sequential high and low pressure operation system are adopted, thus increasing the pressure, pressing and automatic feeding.

Main application

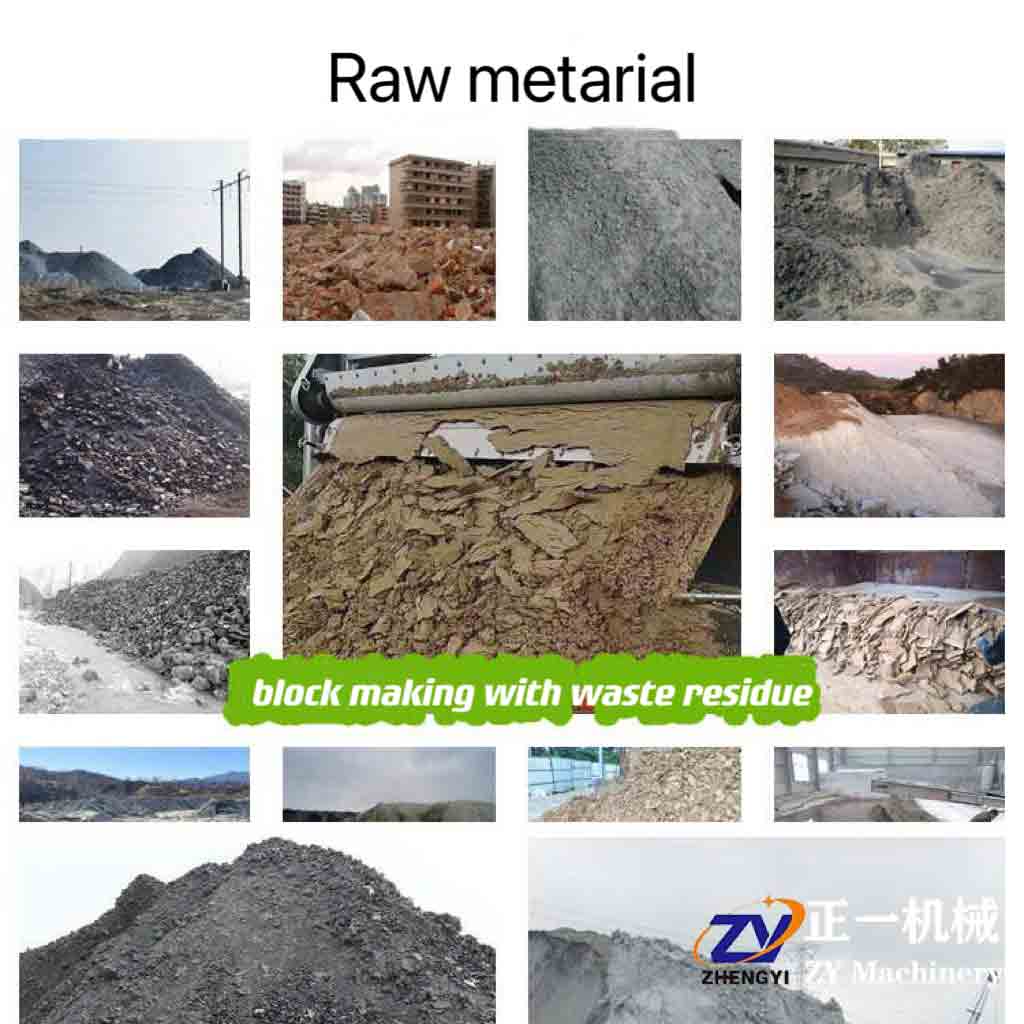

This type of static pressure bricklaying machine has many functions, and can produce all kinds of bread bricks, such as Dutch brick, pavement brick, grass-planting brick, slope protection brick, water-permeable brick, curved brick, Spanish square, hexagonal brick, maple leaf brick, diamond-shaped brick, figure-of-eight lawn brick, double figure-of-eight grass-planting brick and kerb. Just change the mold, so as to truly realize multi-purpose of one machine and save the investment cost. The bricks produced by Henan Hydraulic Static Brick Press have high strength, no cracks, low shrinkage and high product quality. Various pavement bricks, permeable bricks and municipal bricks can be produced by adding a small amount of cement to waste stone powder and other wastes. Note: This machine belongs to environmental protection products: the production and use of clay bricks are restricted by the state, and the new type of baking-free bricks, as a new type of building materials strongly supported by the state, have the advantages of protecting cultivated land, environmental protection and energy saving, low cost, less investment and local materials.

Henan Zhengyi Building Materials Machinery Manufacturing Co., Ltd. is a large-scale manufacturing enterprise specializing in the production of hydraulic brick machines, mobile brick making machines, solid waste treatment brick making machines, and other equipment. The company was established in 2006. Since 2006, the company has invested funds in the research and development of a series of new environmentally friendly materials and equipment.

The company has grown rapidly with scientific management methods, continuous improvement in manufacturing processes, and innovative manufacturing concepts. Adhering to the policy of "enterprising, pragmatic, rigorous, and united", we continuously explore and innovate, with

technology as the core and quality as the life. We wholeheartedly provide you with highquality equipment manufacturing and good after-sales service.

What we offer ?

Pre-Sales Service.

(1) Inquiry and consulting support.

(2) machine test performance

(3) View our Factory.

After-Sales Service

(1)Training how to instal the machine, training how to use the machine.

(2)Engineers available to service machinery oversea

As an international enterprise, in response to the national policy of encouraging enterprises to go global, it actively expands overseas markets, and its products are exported to more than 30 countries and regions (the United States, Australia, Bangladesh, Cambodia, Vietnam, Thailand, Angola, Algeria, Sudan, Saudi Arabia, Russia, Brazil, Venezuela, New Zealand, Indonesia, Timor-Leste, Tanzania, Malaysia, Mauritania, Kenya, the Philippines, etc.), and have established good trade partnerships with local enterprises.