Sand Washing Machine And Dehydration Machine

Products Description

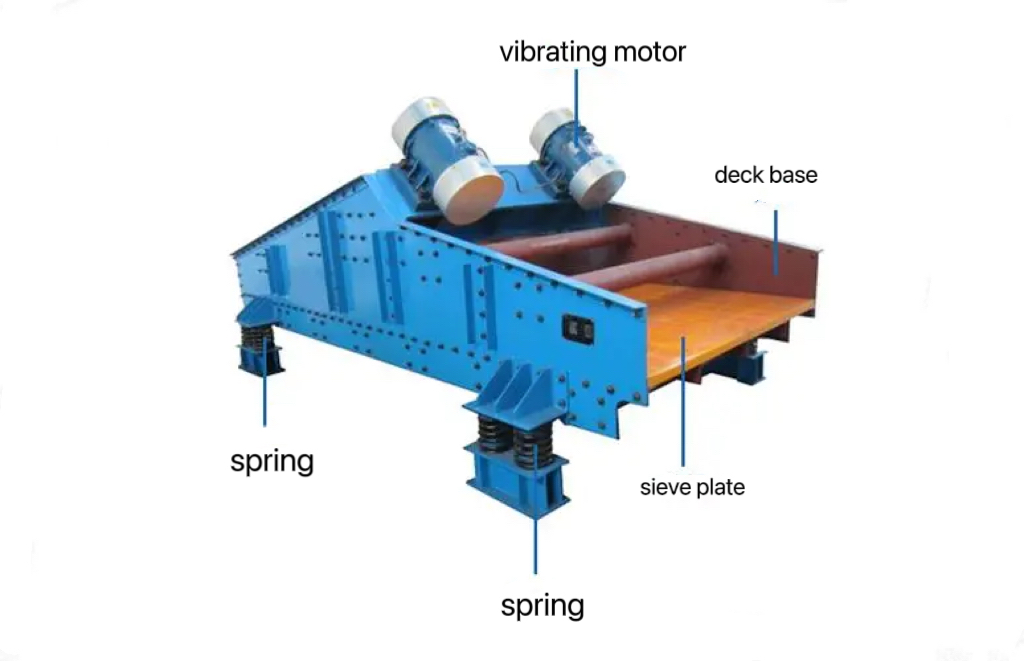

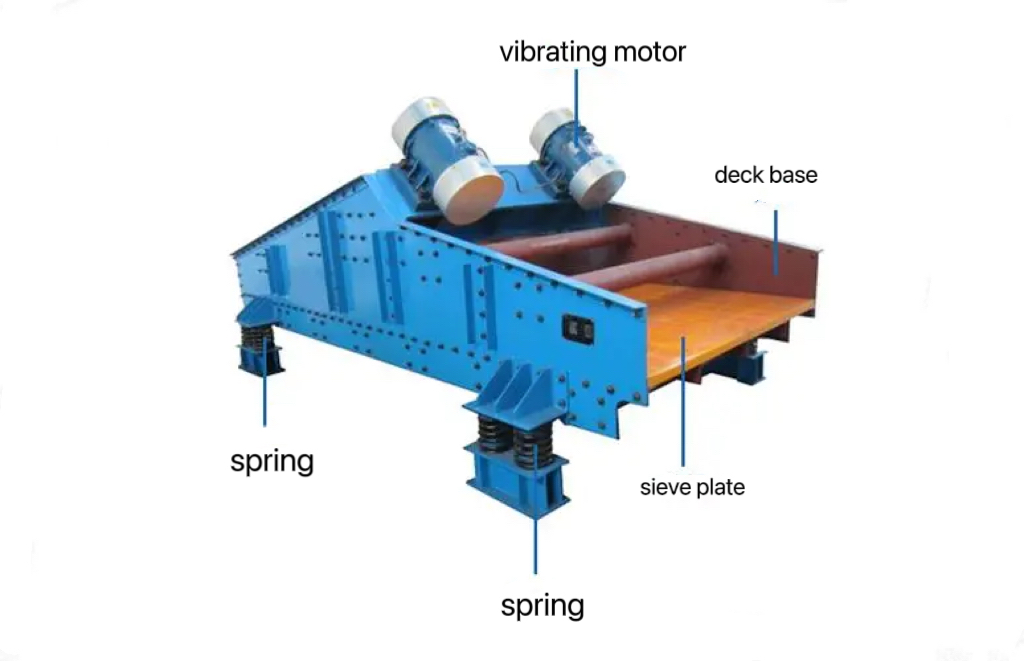

Ine sand recovery machine

Fine sand recycling machine through the excitation force to change the water tension on the surface of the slurry, slurry water

through the screen mesh to become under the screen, and fine materials are screen mesh blocking the formation of the filter layer

by the vibration force affects the forward movement of the discharge. It is widely used for product classification in mining, metallurgy, construction, highway, railroad, water conservancy and chemical industry. Especially for river cleaning, sand and gravel quarry, mineral processing production line, coal mine sorting and so on.

Working Principle

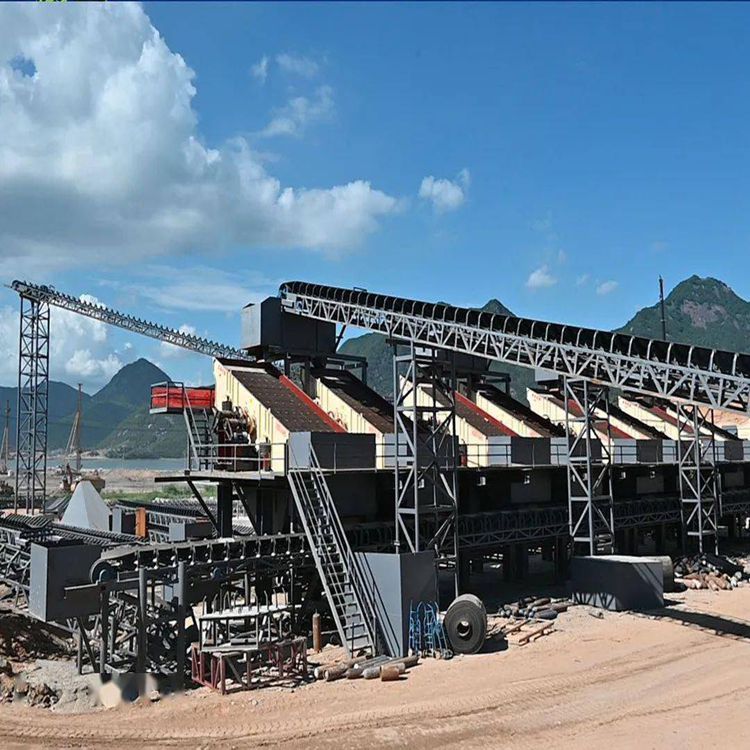

Structure: mobile trailer chassis, screening device, washing device, dehydration recovery device, pump and motor components, conveyor belt, electronic control and hydraulic system.Work Flow: material artificial sand or natural sand, feed through belt machine to screening device, sieve material is transported from belt machine to yard as finished product, sieve material enters sand washing device through flow trough, and carry on full soaking, stirring, cleaning in sand washing device, the cleaned material is dehydrated and recovered when transported to front-end dehydration equipment.

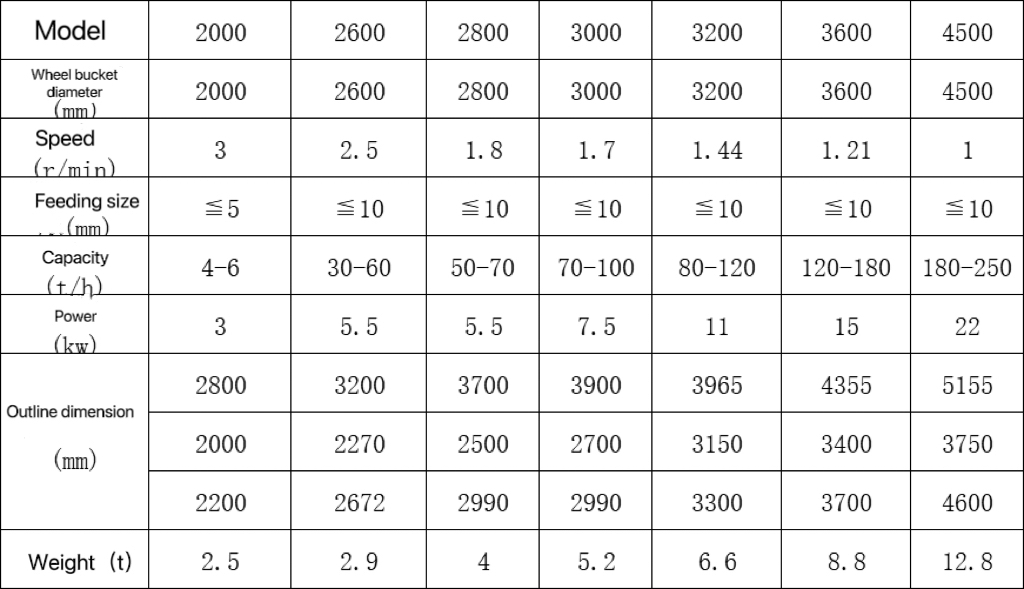

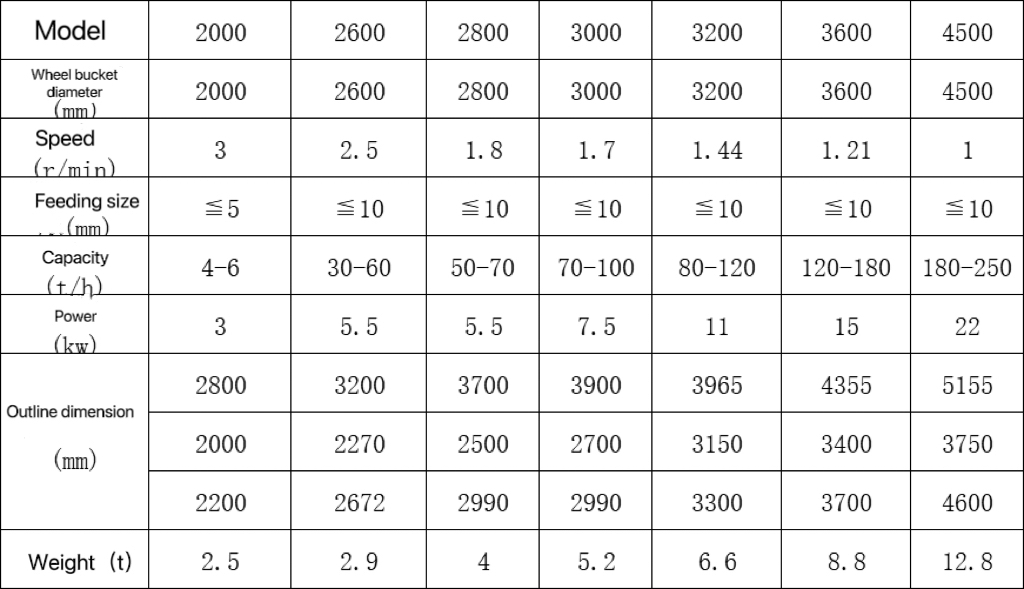

Specification

1. Highly integrated, automated design, eliminating cumbersome site layout, foundation installation and other tasks.

2. Mobility, the machine uses flexible, convenient, efficient, environmental protection, intelligent screening, washing, recycling, dehydration workstation.

3. Integrated whole set of units eliminates the complicated site infrastructure installation operation of the split components, reduces the consumption of materials and working hours, and the reasonable and compact space layout of the units, and improves the flexibility of the site stationed.

4. Reduce the cost of material transportation, materials can be processed on site, greatly reducing the cost of material transportation.

5. Customized service, according to different material types, product requirements, to provide more flexible process and equipment configuration to meet user process requirements.6. Adaptability, it can run independently, but also with crushing equipment, and back-end tailings treatment equipment group, joint operation.

Packing & Delivery

We have exported more than 100countries like Russia,Kazakhstan,Uzbekistan,Kyrgyzstan, Peru,France, United Arab

Emirates,Philippines, Thailand, Viet Nam,Cambodia,Africa etc.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging serviceswill be provided.

What we offer:

1)We can provide customers with high-level technical consulting services and high-quality complete sets of equipment

(2)We can develop and formulate advanced technological processes

(3)We provide excellent mechanical equipment

(4)We have a comprehensive range of solutions to help you build a modern sandstore factory with high quality ,high automation ,high output and high return

why choose us:

(1).Our company established in 2003,Build own factory in 2007 has more than 20 years of sandstore production line

experience,

(2)Our company Is a member of China Sandstore Association,

(3).We have our own R&D team, the quality of products to meet ISOand EU quality system certification, strong technical force

(4). our company also provides perfect after-sales service.

1. who are we? We are based in Henan, China, start from 2007,sell to Western Europe(11.11%),Eastern Asia(11.11%),Mid

East(11.11%),Oceania(11.11%),Africa(11.11%),Southeast Asia(11.11%),Eastern Europe(11.11%),South America(11.11%),NorthAmerica(11.11%). There are total about 101-200 people in our office.

2. how can we guarantee quality? Always a pre-production

sample before mass production; Always final Inspection before shipment;

3.what can you buy from us? AAC block production line,brick making machine,charcoal ball press machine,mining equipment,sand making machine

4. why should you buy from us not from other suppliers? The company can provide customers with high-quality autoclaved aerated block/sandstone production equipment and technical services. we can formulated advanced technological process of aerated block and sandstone production line

5. what services can we provide? Accepted Delivery Terms: FOB,CIF,EXW,CIP,DDP; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment

Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Cash; Language

Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.