What are the technological principles and processes for investing in AAC block production line?

Aerated brick has the advantages of light bulk density, high thermal insulation performance, good sound absorption effect, certain strength and machinability, and rich raw materials, especially using fly ash and sand as raw materials, which can not only comprehensively utilize industrial waste residue, control environmental pollution, but also create good social and economic benefits. Aerated brick equipment products are a wall material that replaces traditional solid clay bricks and have good development prospects.We introduce the somersault production process of Xiasha aerated brick equipment:

(1) Raw materials are injected into a pouring mixer, evenly stirred and put into a mold.

(2) in the mold, natural curing. After a certain temperature and time of pre-cultivation.

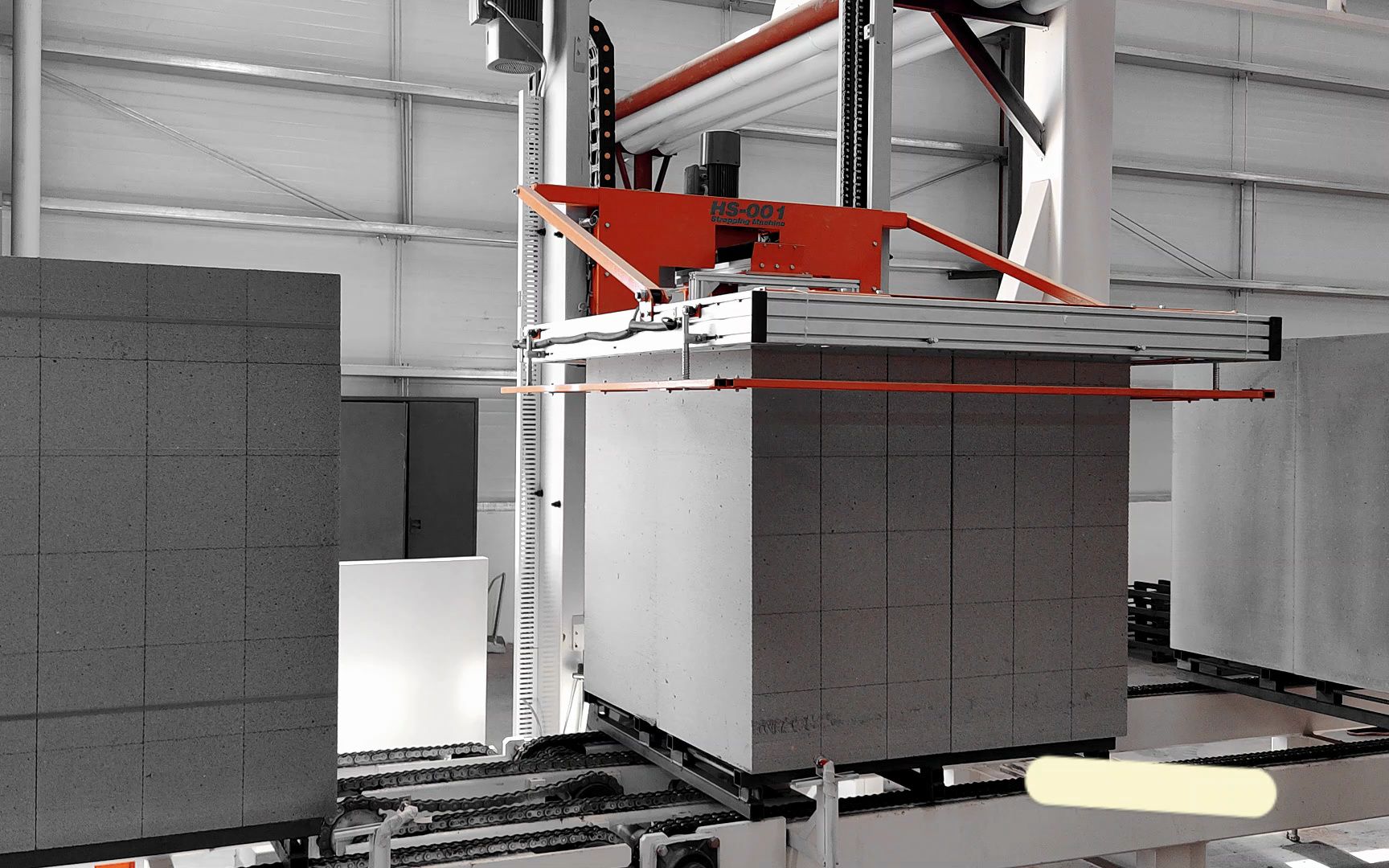

(3) After the blank reaches a certain hardness, the mold and the blank are hoisted to the cutting machine by the overturning spreader, and the overturning spreader completes the following functions: the mold is overturned 90 degrees in the air.

(4) One side plate of the mold becomes the bottom plate for supporting the blank until the finished product is steamed, and then it is hung on a trolley or a cutting support frame to finish mold opening and demoulding.

(5) The removed mold frame and the returned steam-cured side plate are reassembled into a mold to be cleaned, and then sprayed with oil for re-pouring.

(6) the blank is cut on six sides in a cutting machine step by step, the two sides of the blank are cut vertically, and then the blank is cut vertically and horizontally.

(7) transverse horizontal or side knife cutting.

(8) The cut embryo is hoisted to the steam curing trolley by the semi-finished product spreader and the bottom plate.

(9) then group into an autoclave.(10) steaming at high temperature.

(11) After steaming and curing, the product is taken out of the kettle, and the finished product is stacked or crashed and packed by the finished product spreader.